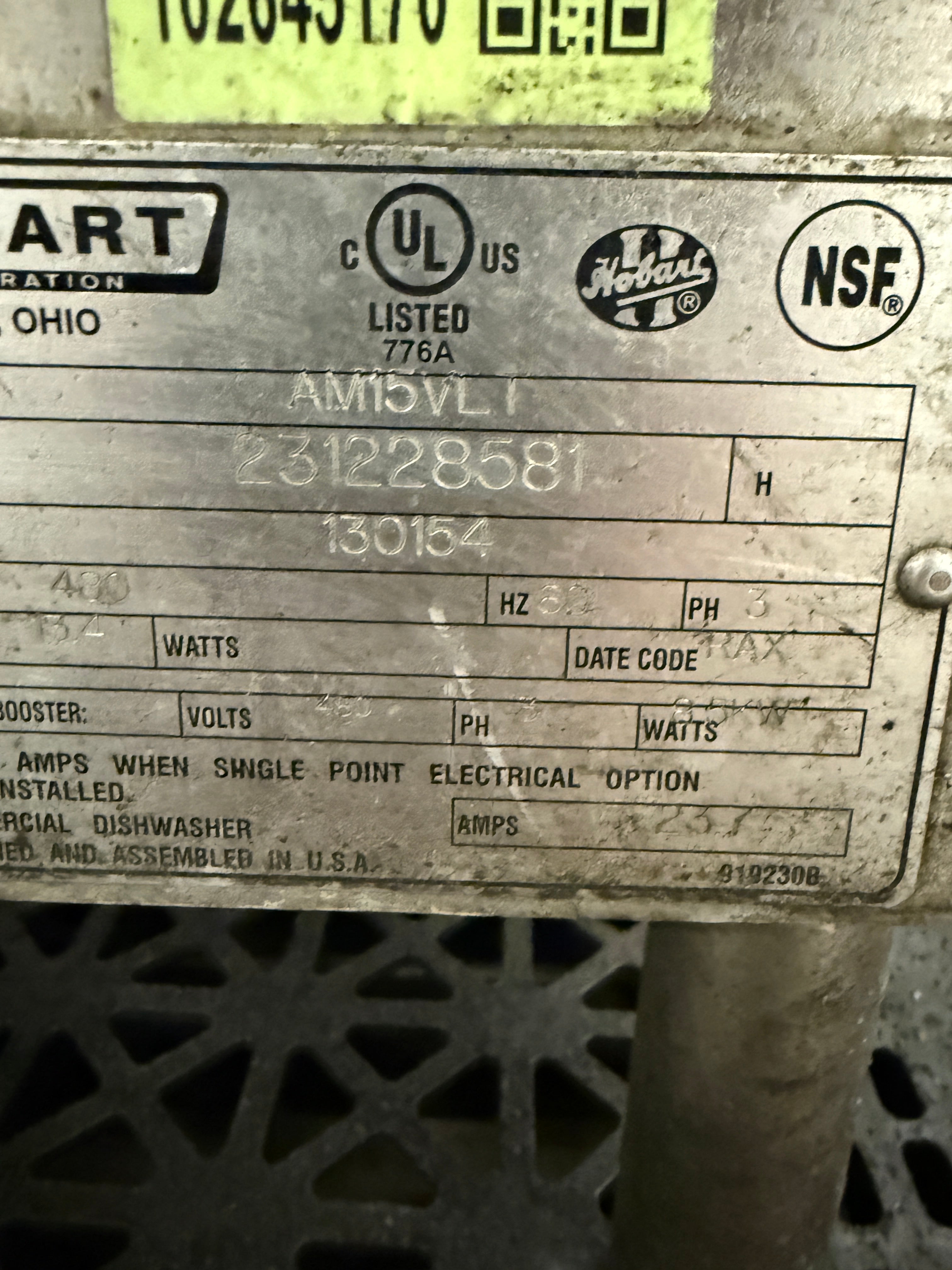

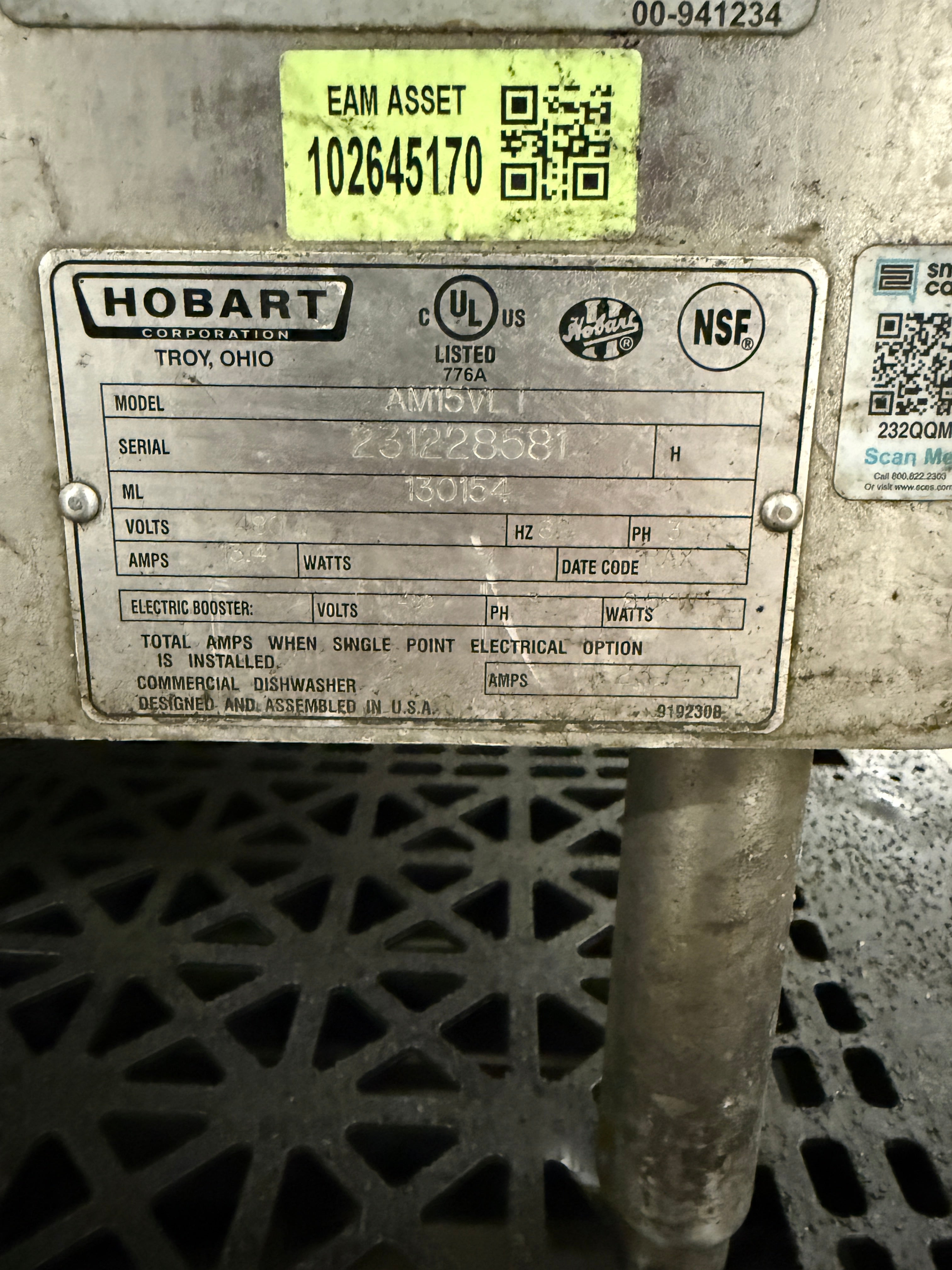

Description

Located in Phoenix

Contact Jim: (602) 907 5336

sales@surplusassetmanagement.com

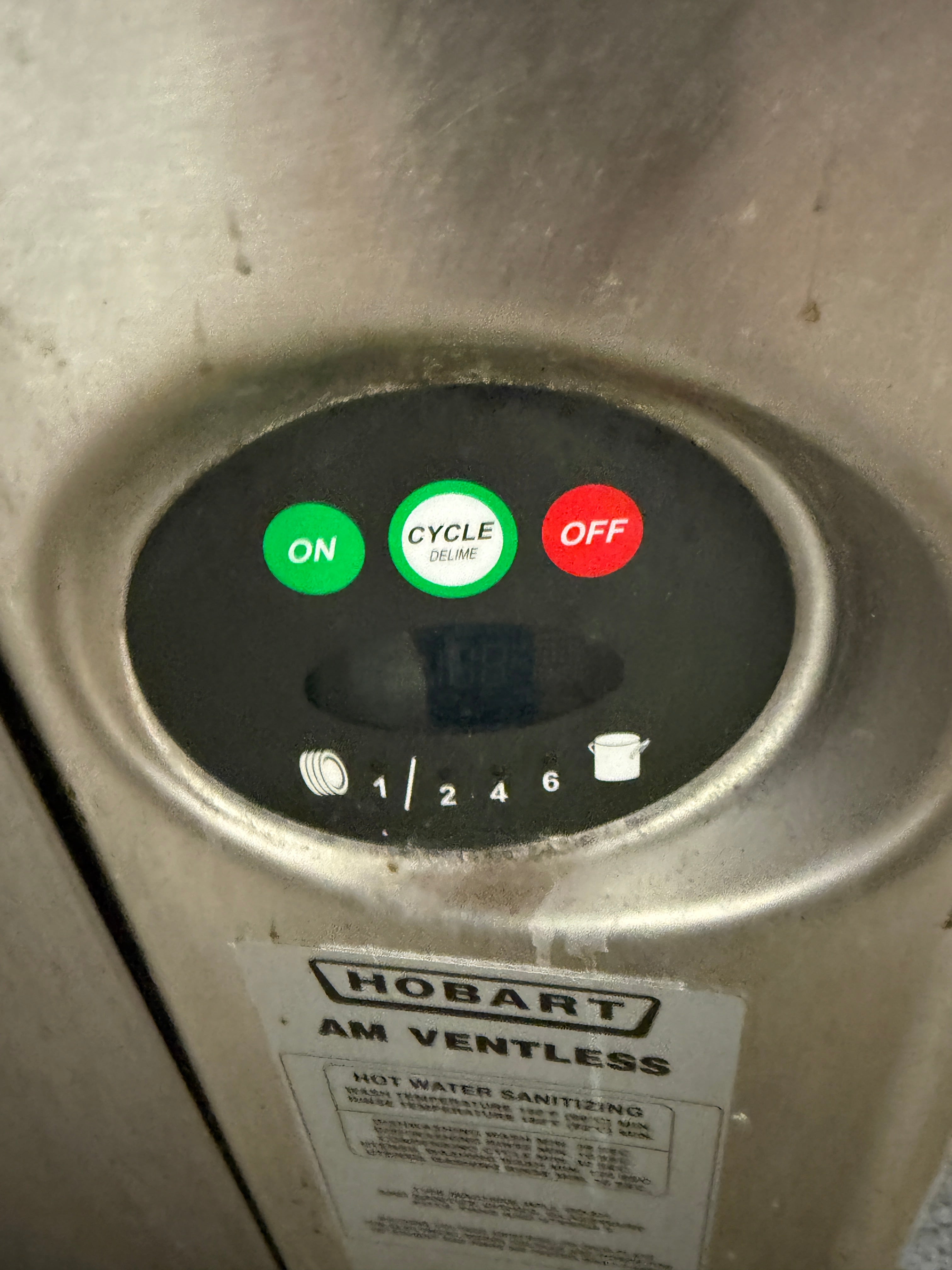

The microcomputer-based control system is built into the Ventless Door-Type Dishwasher.

Water hardness must be controlled to 3 grains of hardness or less for best results.

CONSTRUCTION:

Drawn tank, tank shelf and feet constructed of 16 gauge stainless steel. Wash chamber and front trim panel above motor compartment are polished, satin finish. Frame is 12 gauge stainless steel, chamber is 18 gauge, and removable trim panels are 20 gauge.

CHAMBER LIFT:

Chamber coupled by stainless steel handle, spring counterbalanced. Chamber guided for

ease of operation and long life.

WASH PUMP:

With stainless steel pump and impeller, integral with motor assures alignment and quiet operation. Pump shaft seal with stainless steel parts and a carbon ceramic sealing interface. Easily removable impeller housing permits ease of inspection. Capacity

160 GPM. Pump is completely self-draining.

WASH PUMP MOTOR:

Built for Hobart, 2 H.P., with inherent thermal protection, grease-packed ball bearings, splash-proof design, ventilated. Single-phase is capacitor-start, induction-run type. Three-phase is squirrel-cage, induction type.

RINSE PUMP:

Powered by a 1 ⁄15 H.P. single phase motor, the rinse pump is made of high strength engineered composite material. BLOWER: The condenser blower is an all stainless

steel forward curved centrifugal wheel powered by a 1 ⁄20 H.P. TEFC single phase motor for nearly silent operation.

CONDENSER COIL:

The condensing system using a tube and fin coil constructed of copper and corrosion

resistant aluminum.

MICROCOMPUTER CONTROL SYSTEM:

Hobart microcomputer controls, assembled within water-resistant enclosure, provide built-in performance and reliability. The microcomputer control, relays and contactors

are housed behind a stainless steel enclosure, hinged to provide easy access for servicing. The line voltage electrical components are completely wired with 105°C, 600V thermoplastic insulated wire with stranded conductors. Electrical components are

wired with type ST cord. Line disconnect switch NOT furnished.

CYCLE OPERATION:

The microcomputer-timing program is started by closing the doors, which actuates the door cycle switch. The cycle light turns ON. The microcomputer energizes the wash pump motor contactor during the wash portion of the program. After the wash, a dwell permits the upper wash manifold to drain. At the end of the dwell, the final rinse pump is energized. After the final rinse pump turns off, Sani-Dwell permits sanitization to continue. The Rinse display remains on during this period. The Blower and Cold Water Valve turn on for 30 seconds to condense the vapor laden air inside of the chamber. The display

shows a count down time (in seconds) during this operation. After the 30 seconds is complete the Cycle Light turns OFF, completing the program. If the microcomputer is interrupted during a cycle by the door-cycle switch, the microcomputer is reset to the

beginning of the program. 40 racks per hour – 87 seconds: 38 Second Wash, 2 Second Dwell, 10 Second Rinse, 7 Second Sani-Dwell. 30 Second Condensing. Manual wash cycle selector also provides selection of 2-, 4- or 6-minute wash cycles plus condense time for

heavier washing applications.

WASH:

Hobart revolving stainless steel wash arms with unrestricted openings above and below provide thorough distribution of water jets to all dishware surfaces. Arms are easily removable for cleaning and are interchangeable. Stainless steel tubing manifold

connects upper and lower spray system.

RINSE:

Rotating rinse arms, both upper and lower, feature 14 rinse nozzles. The stainless steel upper and lower rinse arms are easily removable without tools for inspection and are interchangeable. The motor driven rinse pump gives constant rinse pressure regardless

of water service supply pressure. Easy open brass line strainer furnished.

HOT FILL:

Microcomputer controlled fill is supplied from the hot water service connection. It enters the machine through an air gap system which protects the potable water supply from contamination. Ratio fill method is used giving the correct fill at any flowing water pressure.

COLD WATER:

Cold water supplied to condenser coil is heated during the condensing period at the end of each cycle. This pre-heated water is supplied to the booster for subsequent heating.

Estimate shipping

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.